Why use polyester for conveyor belts?

Conveyor belts are the driving force behind conveying operations. There are many different types and materials on the market for a wealth of applications. However, there are several different textiles that play an important role in conveyor belts.

Uses of textiles in conveyor belts

To provide strength for tensioning

To provide strength for handling loads

Adding rigidity or stiffness, "giving it body"

Improves mechanical fastener holding power

Improves wear on the conveyor bed

Reduces sliding resistance on products or conveyors

Fibers Used in Conveyor Belting

Synthetic - aramid, nylon, polyester

Nylon.

Nylon core is used to provide high strength in certain flour, paper, box and wood applications for conveying products or transmitting power. It is used as a width fibre (weft) in conveyor belts to increase tear resistance and fastener retention and to resist abrasion of construction material products.

Features and characteristics

High strength

High elasticity - stretch and shrinkage

Moderate absorption

Moderate elongation

High cutting and abrasion resistance

High resistance to mould and mildew

Solid woven polyester is used as a durable and low-cost option for general transport, with specific uses in wrapping, parcel and baggage applications. Polyester is used as an inexpensive carcass for multi-layer conveyor belts in the length of the weave (warp), the width (weft) or in both directions of the weave. Spun polyester produces less noise and is used when higher speeds are used in longer (shorter) slider bed applications.

Features and characteristics

High strength

Low elasticity - stretch and shrinkage

Moderate absorption

Moderate elongation

Moderate cutting and abrasion resistance

Low temperature resistance

High resistance to mildew

Aramid (Aramid).

Conveyor belts must withstand high temperatures and fire retardant glass applications, heavy duty applications near industrial furnaces or conveying hot products discharged from heat treatment processes, and heavy duty applications that are resistant to high or heavy impact.

Features and characteristics

High strength

High bulk - coarse, thick fibres

High modulus - low elongation

High flame resistance

High impact resistance

High temperature resistance

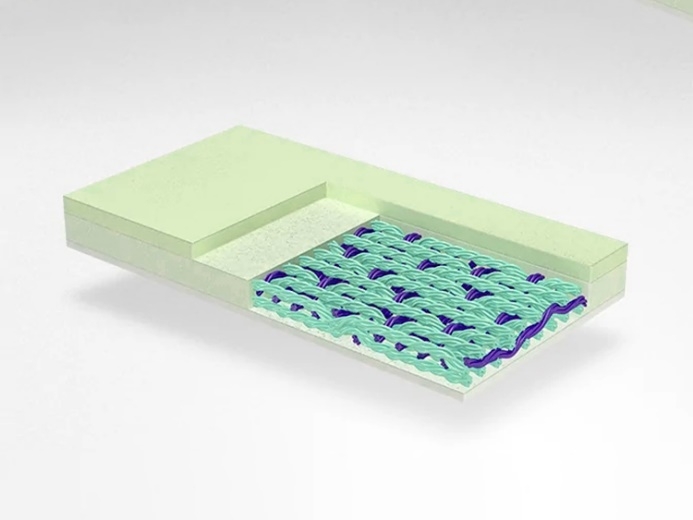

After continuous efforts and experimental tests by PFM engineers, PFM has developed an innovative product, a polyester mesh conveyor belt that can be passed through chain rods.

Polyester linear sieve mesh belts are commonly used in the drying process in food production, but the polyester mesh belt itself is not supportive. If we want to support the product during processing, we need to install support bars under the belt. Before PFM Screen produced polyester mesh belts with rod pockets, the factory usually used cable ties to secure the chain rods to the belt.

PFM Screen's engineers created an innovative design and modification to the existing weaving machine. The first polyester mesh belts are now being successfully used in puffed food processing plants.

If you are interested please contact us as soon as possible.

评论

发表评论