Paper forming fabrics are utilized in the whole paper making procedure to help to make paper

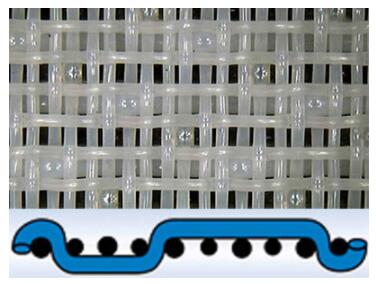

1.5 layer forming fabrics are improved products of single-layer nets, and have actually boosted multilayer net properties by raising the density of the surface weft threads of stickers. The smoothness of the sticker label surface, pulp fiber retention, dewatering performance, and also cleansing performance are all considerably improved. The negative aspect is that it is not wear-resistant and has a brief life span. As soon as the foreign matter has fallen under the internet, the net will certainly not be fixed.

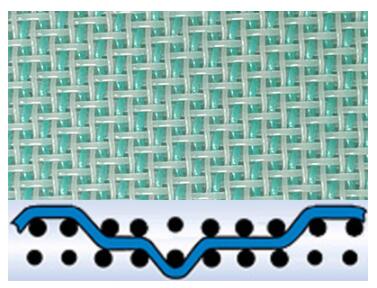

Double layer forming fabrics usually weave two layers of weft strings right into horizontal double-layer weaves. Compared with single layer forming fabrics, the warp and also weft lines have high density, as well as consequently have the qualities of hard contraction and dimensional stability. The cable diameter and material of the paper-side and machine-side weft yarns can be arbitrarily selected according to the application requirements, thereby enhancing internet scratches, surface area appearance, smoothness, and also life span. The three-dimensional area is big as well as the dewatering residential or commercial property is superior. The dewatering pressure does not straight influence the paper. As a result of this, the fiber retention rate as well as the fiber loss price are improved.

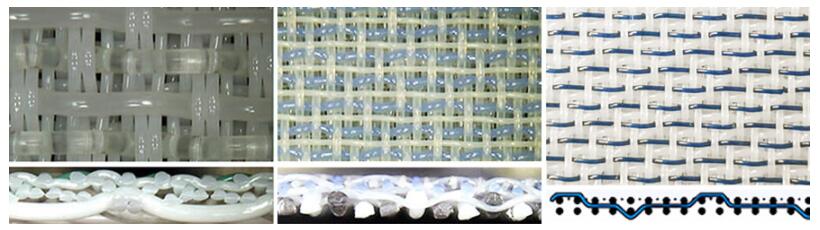

2.5 layer forming fabrics, as an improved type of double layer forming fabrics, enhances the thickness of the sticker label surface area weft, boosts the number of paper support factors, properly enhances the internet mark and fiber retention price, and also boosts the surface buildings of the paper. The density of non-stick surface weft yarns can be lowered, to ensure that the inner three-dimensional area of the web is raised and the dewatering efficiency is enhanced.

Water drainage, forming, retention, and also the impact on the paper surface of the web are really vital in the slurry forming procedure. According to the existing water drainage idea, enhanced slurry development normally has to be at the expenditure of retention, low-dose retention helps transform the set properties, as well as it is possible to boost shaping by enhancing rough flow results. Only when the forming fabrics is at high mechanical retention, decreasing the dose will certainly work. The SSB triple layer forming fabrics has these buildings. Its qualities are: Compared with dual layer forming fabrics and also 2.5 layer forming fabrics, SSB nets with architectural weaving style have higher fiber support, and open uniformly spaced meshes have a larger area and also more Uniformly little meshes make the drain much more consistent, as well as the DC-type drainage networks also make water drainage much easier, have excellent air permeability, as well as improve the tension cross-section of the mesh.

评论

发表评论