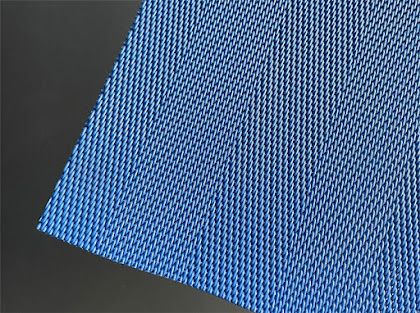

Plain Weave: Tensile Polyester Mesh Screen

WEAVING TYPES AND PATTERNS 1. Plain Weave; 2. Spiral Loops Link Weave. Plain Weave: Tensile Polyester Mesh Screen We can supply 20mesh/ inch, 25 mesh, 30 mesh, 40 mesh, 50 mesh, 60 mesh to 420 mesh, with a maximum roll width of 3750mm. The low elongation dacron mesh is replacing monofilament polyester mesh in screen printing with quick tension forming, high strength, stable tension, and fast printing. Screen filter mesh made with material of PA and PET, polyester, and nylon material. Nylon polyester mesh is widely used in liquid and air filtering, mainly textile printing and dyeing, printing plate, electronic printing, ceramics, glass printing, and other industries. Supplied in two forms of processing: needlefelt or woven mesh fabric. We offer 20~1200 micron filter mesh in polyester and nylon material. Spiral Link Weave: Mesh Belt, Supplied with or without Filled Wire Spiral mesh is made with round or flat wire in the form of edgeless, loop link, with filling wi...