Category and attributes of paper forming fabric products

Paper forming fabrics are utilized in the whole paper making procedure to help to make paper.

Category and also characteristics of synthetic fiber forming fabrics.

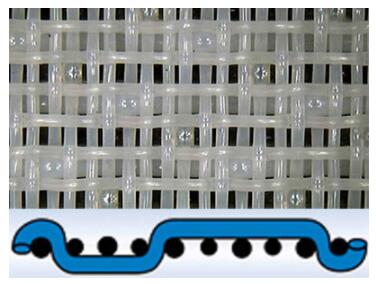

As a result of its soft material, synthetic fiber forming fabrics can be made for numerous sort of weaving. General forming fabrics in the world today, according to its structure can be roughly divided into single layer (solitary layer of woven) and multilayer (multilayer woven), multilayer includes dual (dual layer weave), 3 layer (triple layer weave), etc.

Solitary layer forming fabrics can be split into ring internet and also plug-in internet according to their knitting procedures. Ring network, likewise referred to as a limitless network, is an endless ring network that is woven directly from an impend. Its structural features are weaving, the longitudinal direction of the paper equipment (MD) for the weft, without the joint fiber yarn for dual weaving at the interface. The longitudinal direction of the plug-in mesh weaving is a warp thread, which is first knitted right into a single piece. Then, completions of the solitary item are inserted by warp strings to form an endless net.

1.5 layer forming fabrics are improved products of single-layer nets, and have actually boosted multilayer net properties by raising the density of the surface weft threads of stickers. The smoothness of the sticker label surface, pulp fiber retention, dewatering performance, and also cleansing performance are all considerably improved. The negative aspect is that it is not wear-resistant and has a brief life span. As soon as the foreign matter has fallen under the internet, the net will certainly not be fixed.

评论

发表评论