Define the ideal material and fiber

1. Define the ideal material and fiber

▸Polyester monofilament filter cloth

Made of high-strength, low-stretch polyester monofilaments. Smooth surface for easy cake discharge, acid-resistant, wear-resistant and high- The normal use temperature is less than 130 °C (266 °F), and the instantaneous use temperature is 150 °C (302 °F). The normal use temperature is less than 130 °C (266 °F), and the instantaneous use temperature is 150 °C (302 °F).

▸Polyester multifilament filter cloth

The series of filter cloth is weaving by the polyester filament in multi-strand. It is acid-resistant, high strength, better intercept ability for fine It is acid-resistant, high strength, better intercept ability for fine particles, but more difficult to clean than monofilament due to the multi-fiber. The normal working temperature is no more than 130 °C (266 °F), and the instantaneous working temperature is 150 °C (302 °F).

▸Polypropylene (PP) monofilament filter cloth

Made of polypropylene high-strength monofilament, smooth surface for easy cake discharge, acid and alkali resistant, hydrolysis, oxidation and The normal working temperature of PP filter cloth is less than 90 degrees Celsius, and the instantaneous use temperature is 90°C (194 °F ).

▸Polypropylene (PP) multifilament filter cloth

Made of polypropylene monofilament in multi-strand, smooth surface, acid and alkali resistant, hydrolysis, oxidation and mildew resistant, high strength, better intercept ability for fine particles, but more difficult to clean than monofilament due to the multi-fiber. The normal working temperature of PP filter cloth is less than 90 degrees Celsius, and the instantaneous use temperature is 90°C (194 °F).

2. Select the optimal weave

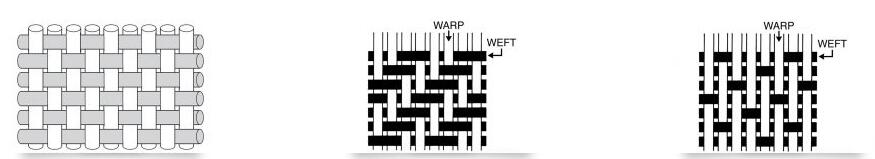

a. Plain weave b. Twill weave c. Stain weave

3. Choose the suitable air perm

High permeability filtering efficiency, but low particle retention rate, small permeability, good particle retention effect, but reduced filtration speed. We will help you choose the most suitable type of filter cloth to get the best filtration yield.

Composite double woven tape filter cloths made from monofilament are the most widely used, due to their many advantages as follows.

●Two layers for filtration and support respectively.

●Dense and smooth surface, good filtration performance, easy to dislodge the filter cake and good resistance to clogging.

●Favorable to the side flow of slurry and increase the effective filtering area of the filter cloth.

●The lower layer woven by thicker yarns has larger pore size, which acts as a support member, helps drainage and promotes the fabric to adhere firmly to the rubber belt or drum.

●The tensile strength is better than that of single-layer and resists bending to avoid wrinkling during filtration.

评论

发表评论