The Problems and Solution of the Paper Making Machine Felt

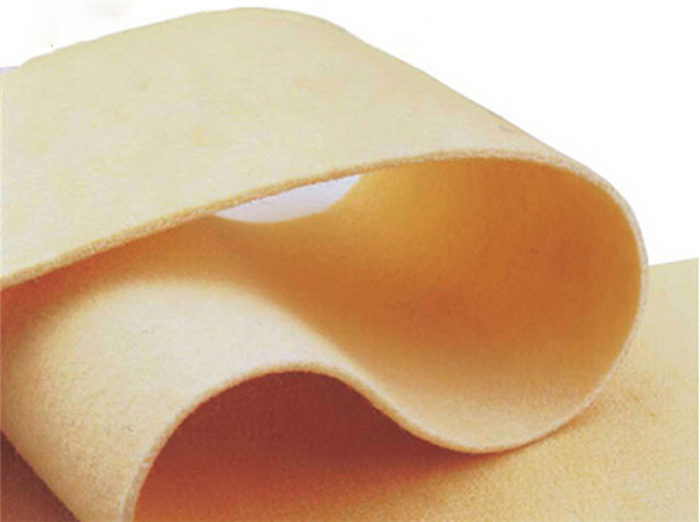

The Full Circle Translucent on the Felt

When this happens, check whether there is impurities in the pastern axes or whether there is a hard spot on the felt guide roller.

Felt Fluff on the Felt

Vertical fluffing generally caused by the unclean felt roller surface or rough vacuum suction box panel, may be local fluff or the whole fluff; Transverse fluff may be caused by the desynchrony of felt and press roll in press section.

The Break of the Felt warp and weft

The break of the felt warp and weft is usually caused by the damage of hard objects.

Sometimes the pulp bolts may made holes on the felt. Also, the fine hard objects such as sand, broken glass in the pulp will make the felt strength decline, the felt warp and weft break. Flakes or punctate appeared in felt, warp and weft broken, may be caused by chemical corrosion, which is low fiber strength. The break of edge warp mostly due to friction with the rack because that the felt is too wide.

Beijing PFM Screen offers dryer fabrics for industrial dryers for drying of various types of material and for drying of paper in drying section of paper machine. If you want to learn more about our products, please contact us.

评论

发表评论