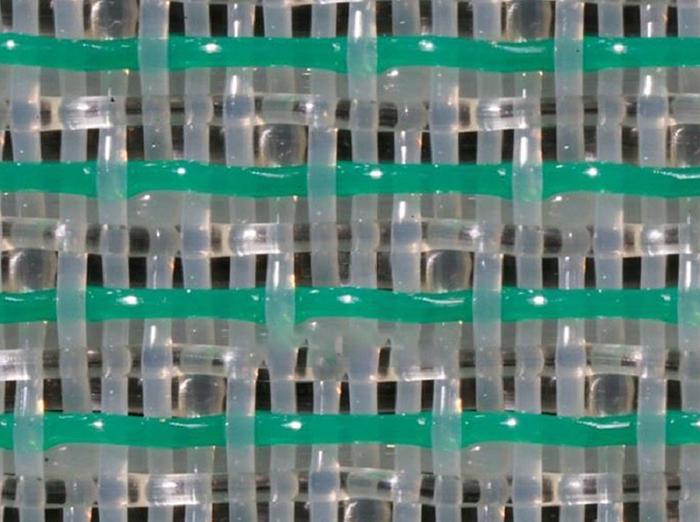

Single Layer Forming Fabric

Single Layer Forming Fabric

5. Guide roller winding pulp: the cleaning water pressure is low and there are many fibers inside the net; the net air permeability is low; there is a problem with the cleaning method. The two and a half layers of the net should be cleaned on the paper outlet surface of the net. Whether the nozzle is clogged, the best distance between the nozzle and the net surface is 15 -20cm.

6. Vacuum box top slurry: improper mesh air permeability, short slurry fiber loss, poor quality of retention aid or small addition amount.

7. Large fluctuation range when the net is running: the corrector is not working properly, and the side cutting of the net is not straight.

8. The net becomes narrow after using for a period of time: local wear of the forming plate, wiper board, vacuum box panel or guide roller causes the marking line of the net to run for a period of time to become slanted.

9. Comparison of the life of the D-type device and the previous net: The addition of the D-type device can effectively solve the two-sided difference of the paper, speed up the dehydration and increase the speed, but the life of the forming net will be reduced, mainly because the water line becomes shorter and the wear is accelerated. General life expectancy is reduced by 1/3 or even 1/2.

Our company also has Single Layer Forming Fabric on sale, welcome to contact us.

评论

发表评论