The Problems and Causes That are Easy to Encounter in the Use of Paper Forming Fabrics

As a Paper Machine Clothing Manufacturer, share with you.

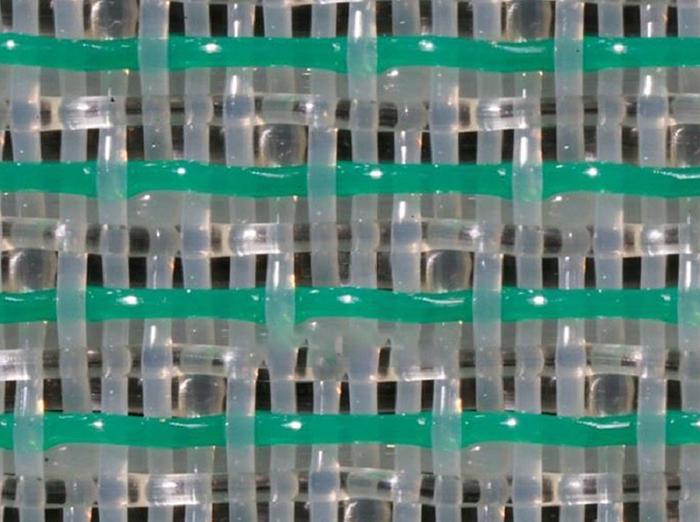

Single Layer Forming Fabric

1. Too fast abrasion of the screen edge: The most serious wear of most paper machines are at the joints with and without vacuum (10-15cm of the screen edge); Solution: 1. Increase the opening of the vacuum box as much as possible. Staggered width. 2. Add normal pressure lubricating water to the edge of the vacuum box. 3. Add stiffeners in appropriate positions. 4. Check whether there are edges or gaps in the side wiper and the vacuum box. Especially the joints of the ceramic panels are weak links 5. Check whether the edges of each roll are severely worn (the diameter becomes smaller after wear, so that the tension of the mesh is smaller than the normal mesh surface and further accelerates the wear)

2. The overall wear is too fast: 1. The panel quality is not good enough. 2. The net tension is too small, the return tension of the single-layer net is 3-4kg/cm, and the return tension of the two-layer forming net is 5-6kg/cm. 3. Poor packing quality. 4. The net has a large air permeability and there is a lot of filler loss, and there are too many filler particles between the net and the vacuum box panel, and the overall wear of the net will be faster. 5. The net air permeability is small and the water filtration is slow, but the vacuum degree increases and the wear is accelerated. 6. The rotation speed of the guide roller and the wire speed are not synchronized. 7. The speed of the upper and lower network is not synchronized.

评论

发表评论