Tips for choosing filter belts

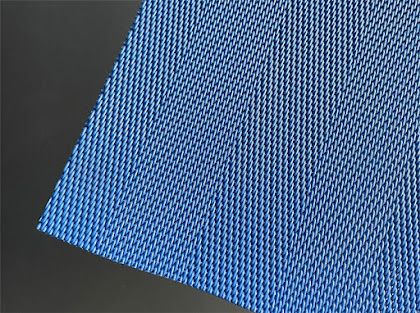

Filter belts is an indispensable supply for many industries. If you want to get quality filter belts products to meet your requirements at a very reasonable price, you must master some skills and methods when purchasing filter belts. Shop around to buy better products. First, choose the filter belts material reasonably according to your own needs. Generally speaking, the filter belt material includes galvanized wire, as well as black steel wire, black iron wire and stainless steel wire. Price and performance vary among different materials. So make a reasonable choice according to your specific needs. Thus you avoid spending unnecessary money. Second, choose the appropriate mesh size of the filter belts. The specifications of the filter belts are various for you to choose. So purchase filter belts products with the appropriate mesh size that fit the functions you need. Third, the type of filter belts production p...